Retorts

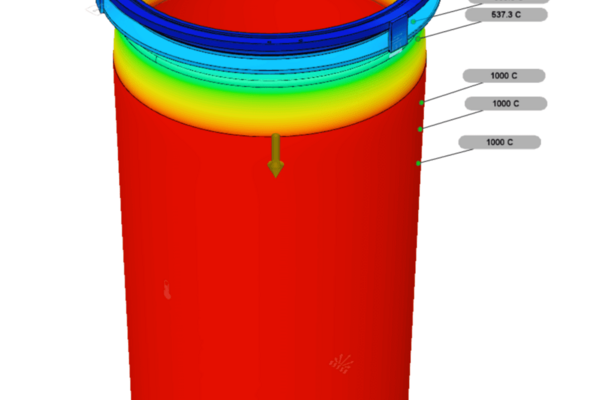

Retorts, whether out of graphite, molybdenum or tungsten, serve to separate the batch from the heating chamber and can be employed for a number of reasons. For example, the process may make it necessary to separate the batch from the rest of the hot zone space in order to protect the furnace from the batch or the batch from the furnace materials. Pyrolysis processes can also make it necessary to set a defined gas feed so that no pyrolysis condensation is produced in the vacuum vessel.

We supply retorts to meet all construction sizes.