Processes & Applications in the Industry

Examples of thermo-physical and thermo-chemical processes.

Casting, annealing, pre-heating, hardening, harden & temper, carburizing, case hardening, nitriding, nitrocarburizing, carbonitriding, tempering, precipitation hardening, high temperature brazing, aluminum brazing, outgassing, ashing, pyrolysis, siliconizing, calcination, carbonization, graphitizing, pre-sintering, sintering, debinding, Spark Plasma Sintering (SPS), synthesis, sublimation, drying, ceramic fireing, crystal growth, Bridgman, Stockbarger, zone melting, diffusion bonding, …

Automotive

Engine, transmission and drive technology in general

Components

- Pistons

- Engine blocks

- Heat exchangers

- Axles

- Shafts

- Bearing components

Processes

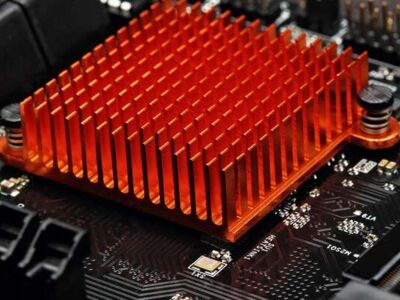

Electronics

Contacts, switches, sensors, coolers, etc.

Components

- Sensors

- Metal Injection Moulding (MIM) components

- Motor components

- Heat exchangers

- Magnets

- Bearing components

Processes

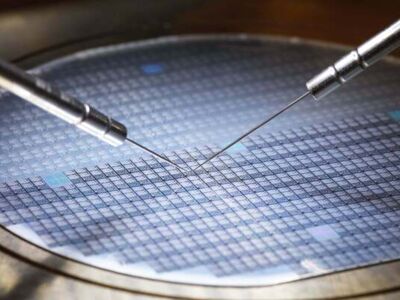

Semiconductor

Production of semi-finished products & production aids

Components

- Transistors

- Solar cells

- Diodes

- LEDs

Processes

Gas and steam turbines

Production and overhaul

Components

- Turbine blades

- Exhaust pipes

- Structural parts

Processes

Aerospace

Landing gears, turbine components, etc.

Components

- Turbine components

- Gear components

- Actuators and sensors

- Aluminum components and heat exchangers

- Structural parts and composite materials

Processes

Medical

Metallic products of highest strength and purity

Components

- IImplants

- Surgical instruments

- Prostheses

- Teeth porcelain or Zirconia

Processes

Fuel Cells

Reformer and heat exchangers

Components

- Heat exchanger

- Reformer

- Stacks

Processes

Military

Arms and ammunition

Components

- Barrels

- Magazines

- Bolts

- Notch and bead sighter

- Ammunition

Processes

Further applications and market segments

Heat treatment processes are used in the production of many products!

Spectacles, watches, jewelry, pharmazie, corporate R&D labs, universities, material research institutes, commercial heat treaters, material vendors, etc.